The SP story begins at the Lee Tire & Rubber Company in a Conshohocken, Pennsylvania, USA in the early 1920s. As part of their business, they braided cotton yarn and coated it with varnish for use as tire beads. When Lee Tire moved to steel rods for their tire beads and decided to close this department, two employees, Bill Bentley, Sr. and Joe Harris, bought the business. On October 23, 1924, Bentley-Harris Manufacturing Company was born. At the same time, a new market for electrical insulation was emerging.

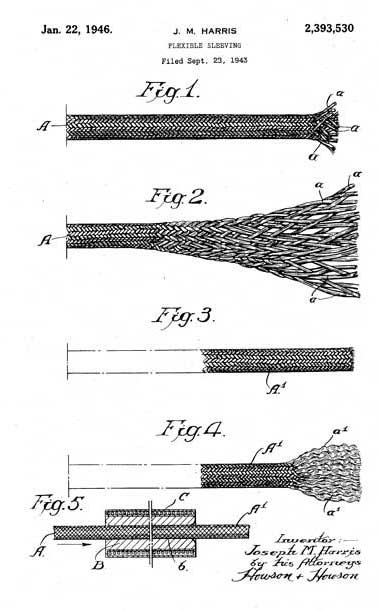

Initially, nearly all of the Bentley-Harris sleeving produced was sold to Atwater Kent, a pioneer radio manufacturer. In the 1930s and 1940s, business expanded to new applications for motors, generators, and transformers. They quickly became the industry leader in quality and innovation in the electrical insulation market. Bentley-Harris became the first to braid fiberglass yarn, the first to coat with vinyl, the first to coat with silicone rubber, and the first to coat with acryl. In 1946, the company was granted its first patent which was for the heat treatment of fiberglass braid.

Steady growth continued in the 1950s as innovative new products were introduced and new manufacturing techniques were adopted. This led to additional patents. Bentley-Harris strengthened its position as a product and quality leader in the insulation market. By the late 1950s, Raychem Corporation took an interest in Bentley-Harris as an acquisition candidate to complement its own innovation in heat shrinkable tubing.

In 1960, Bentley-Harris officially became part of the Raychem family. This brought an increase level of investment in the business. In the coming decade, they continued their market leadership in electrical sleeving and expanded their product offering to meet emerging market needs. In 1967, Bentley-Harris introduced a new line of products for the aircraft market. Their product portfolio also included innovations in thermal gasket products used to seal self-cleaning oven doors which was patented in 1971.

Bentley-Harris Manufacturing Co. was born in 1924 when Bill Bentley and Joe Harris bought the cotton braiding business from Lee Tire and Rubber Company.

To accommodate their growth, all manufacturing activities were moved to Lionville (now Exton) PA in 1976. R&D efforts were expanded to focus on new product development. In 1978, Raychem purchased CFI (Compagnie Française des Isolants) - later renamed Textilver - a textile manufacturer similar to Bentley-Harris, located in Crepy-en-Valois, France. This acquisition added product portfolio strength, collaboration synergy, and supported global customers and markets.

In the early 1980s, Bentley-Harris entered the automotive market with its first product sale of fiberglass insulation for EGR tubes In 1984, they had their first monofilament braid sale for the wire harness market. The need for automotive component protection was growing and their product innovations in wrappable sleeving changed how wire harnesses were protected. White goods including oven seal market growth continued. In 1988, UK based T&N plc (Turner & Newall), recognized the performance and potential of the company and acquired both Bentley-Harris and Textilver from Raychem.

By 1989, N.A. growth required increased manufacturing capacity which led to the first site expansion in Gordonsville, Tennessee. This location allowed them to be closer to customers with full manufacturing as well as an expanded customer service department.

Bentley-Harris was granted its first patent in 1946 for the heat treatment of fiberglass braid.

In the 1920s, a new market for electrical insulation was emerging. Initially, nearly all of Bentley-Harris fiberglass sleeving was supplied to Atwater Kent, a pioneer radio manufacturer.

Early advertising from 1946 spotlights BH fiberglass sleeving for home appliance, radios and industrial equipment applications.

With the financial and management support from T&N, the Bentley-Harris Group of companies experienced accelerated growth in the 1990s. The first automotive sales office was established in Novi, Michigan. Focused efforts were launched to serve heavy truck and N.A. transplant business. Sales and support teams expanded to serve automotive customers including a presence in Germany, Italy, Brazil and the UK. Manufacturing also expanded, including the El Paso, TX site established in 1995. They were the first textile protection supplier to establish a local presence in Japan with a sales office and local supply in 1997. Innovation and growth in the aerospace market also supported their reputation as the pre-eminent supplier of innovative protection products. Patented composite product offerings - such as wing and fuel tank struts for aircraft and antenna structure for satellites - remained part of the portfolio.

In 1998, Federal-Mogul corporation purchased T&N plc, which included Bentley-Harris. While the business continued as a separate product line, Bentley-Harris was rebranded as Federal-Mogul Systems Protection in 2000. The Bentley-Harris brand was retained in certain market segments due to its strong customer recognition.

In the 2000s, Systems Protection expanded its Asia Pacific strategy and expanded local manufacturing in Japan. Customers were also supported from its Thailand location. Product innovations continued as the company expanded into new materials and process areas including non-woven, lamination and extrusion. With continued portfolio growth and strong presence in the Americas, EMEA and AP, the company successfully served both small and large local and global customers.

The original Bentley-Harris Manufacturing site was in Conshohocken, PA (USA), pictured here in 1936.

From 2010 to 2020, Systems Protection focused on geographic expansion to ensure manufacturing was close to its customers to serve their local needs. The following production sites were added during this time: Ayutthaya, Thailand (2012); Bhiwadi, India (2013); Changshu and Tiajin, China (2013 and 2014); Tangier, Morocco (2013); Haiphong, Vietnam (2014), Sejong, Korea (2014), Kimle, Hungary (2015), Queretaro, MX (2016); and Laguna, Philippines (2019). Product innovation continued during this time, seeing growth in aerospace and automotive markets including early entrants into the HEV and EV segment.

In 2021, they completed an extensive renovation of their Exton Innovation Center including an expansion of its world-class technical services lab. In 2022, they continued their market innovation and leadership by launching new products for the EV Battery segment. In 2023, they refreshed their Systems Protection brand logo to reflect their commitment to innovation, to honor the rich history of textile and to embrace their internal and industry acronym of ‘SP’.

Today, SP continues the Bentley-Harris tradition of product innovation and manufacturing excellence. In fact, this has only been possible because of their talented, creative and committed team members working together locally and across the globe to meet the needs of their customers. Since 1924, it has been the people of BH/SP that have driven the success of the business. And it is certain that they will continue to drive success for the next 100 years.

Bentley-Harris / Systems Protection Timeline